No complaints! The most remarkable spinning reel of the year

The arrival of the 25000 The 25000 will change large tuna fishing!

At last, Daiwa is getting serious. The world has few good economic topics, and we do not hear many bright stories for the fishing industry. However, for offshore anglers pursuing their dreams, nothing could be happier. This is the reason why Daiwa is proud to announce the release of the new SALTIGA spinning reel. We would like to take a deeper look at what makes the new reel different from the previous SALTIGA reels. We hope that you will take a look at the new reels at the upcoming fishing shows and experience their evolution!

INDEX

What a surprise! 5 times more durable drag!

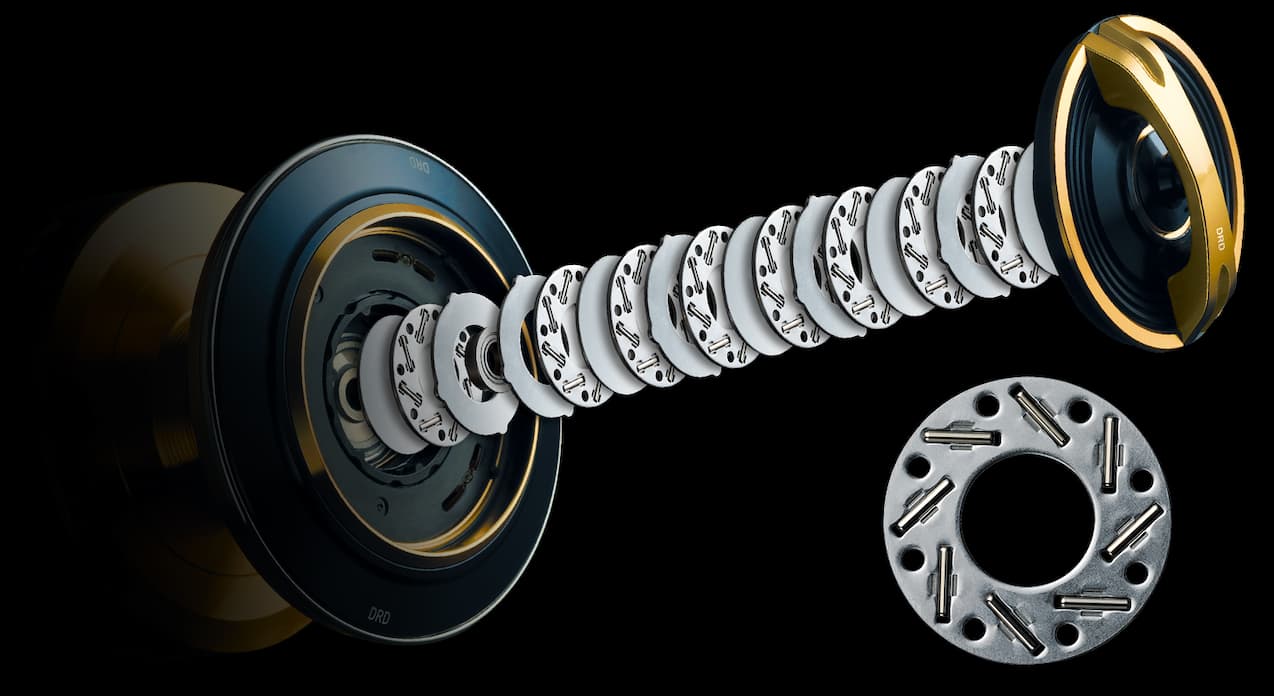

Among the many notable features of the new SALTIGA, the DRD, which is used in the 18000 and larger models, is epoch-making and may change the way we fish for large fish on spinning tackle. As you can see in the photo below, the construction of the DRD is a single metal plate with eight metal rollers, which provides unprecedented drag force. The strength of the drag is 30kg! The strength of the drag is an astonishing 30kg! The durability is more than five times that of carbon washers. Because it is made of metal, even after long hours of fighting, it is free from wear and tear, reduced drag force due to high heat, sticking and seizing of carbon washers, and other problems.

DRD is a revolutionary drag system that uses only metal parts.

(An optional spool using DRD is scheduled to be released as a custom part for the No. 14000 from SLP WORKS.)

Innovation at the heart! Realization of powerful reeling force!

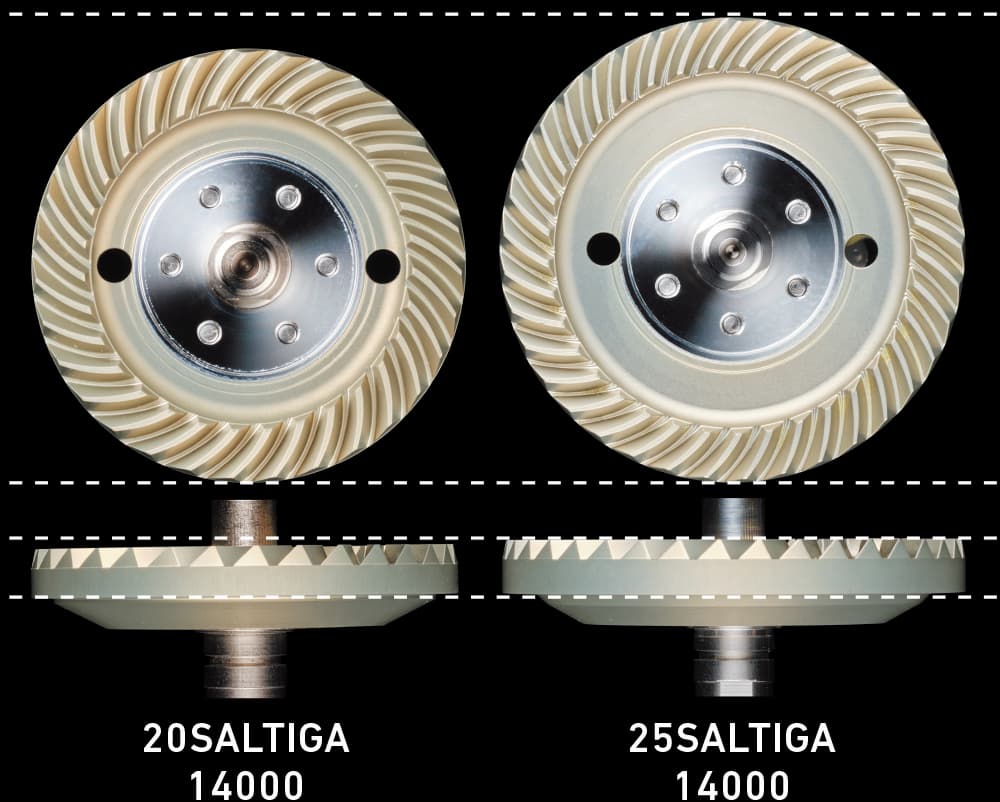

The NEW SALTIGA has a new drive gear, which is the heart of the reel and is built into the monocoque body made of solid full-metal aluminum. As can be seen in the comparison photo below, the diameter of the drive gear in the NEW SALTIGA is approximately 10% larger and 6% thicker than that of the previous model.

In addition, two ball bearings are used in the oscillating mechanism, which increases the oscillation efficiency by about 30%. Like the DRD, this is another epoch-making system that can only be achieved by the “idea-driven Daiwa.

The “strength” of the full-metal aluminum monocoque body is the basis for all the improvements, and the drive gear and oscillator, which are the heart of the system, have been upgraded to an unprecedented level.

Not only have the larger diameter and thicker wall thicknesses increased durability, but the optimized tooth profile has also greatly improved the drive efficiency of the gears.

The oscillating system employs a mechanism with two ball bearings. This greatly reduces frictional resistance and improves oscillation efficiency to the extent that the user can feel the lightness at the beginning of winding under load.

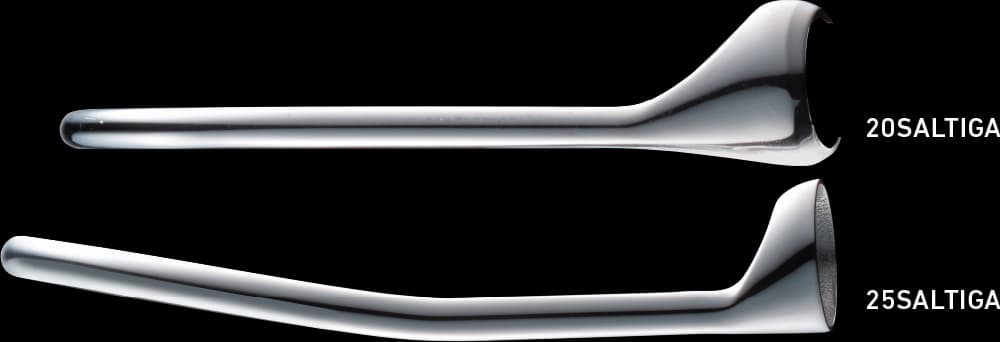

Rotor area has also undergone a major change.

The rotor plays an extremely important role in spinning reels, which convert vertical rotation into horizontal rotation to wind line. The lighter and smoother the rotor can rotate, the more sensitive it becomes. However, simply making the rotor lighter is risky in power games.

The new SALTIGA combines high rigidity with low inertia, and its rigidity has been increased by approximately 7% over the previous model. In other words, flexing under high loads is reduced, so reeling is lighter and hooking and drag performance are improved.

The bail shape and line roller have also been modified. This has made it easier to avoid trouble.

Daiwa’s original rotor shape, which has been highly regarded for its rigidity, has been further developed and its rigidity has been increased by approximately 7%.

The bail is crank-shaped to ensure that tensioned line is guided to the line roller. In addition, the bail opening and closing angles have been reviewed and the spring mechanism has been strengthened. This prevents the bail from opening and closing unexpectedly, which tends to happen when casting.

The durability of the area around the line roller has been greatly improved in the new SALTIGA, with a line roller specially designed for PE line (non-twist buster), which reduces sliding resistance by approximately 3% (when using nylon or fluorocarbon line, the line roller is not designed for use with nylon or fluorocarbon line).

*When using nylon or fluorocarbon line, we recommend replacing the line roller with a twist buster version (sold separately).

The LC-ABS SW, with its new shape in front of the spool, reduces frictional resistance with the line released with reduced yarn, reducing the feeling of stalling in the second half of casting, especially when using thicker line.

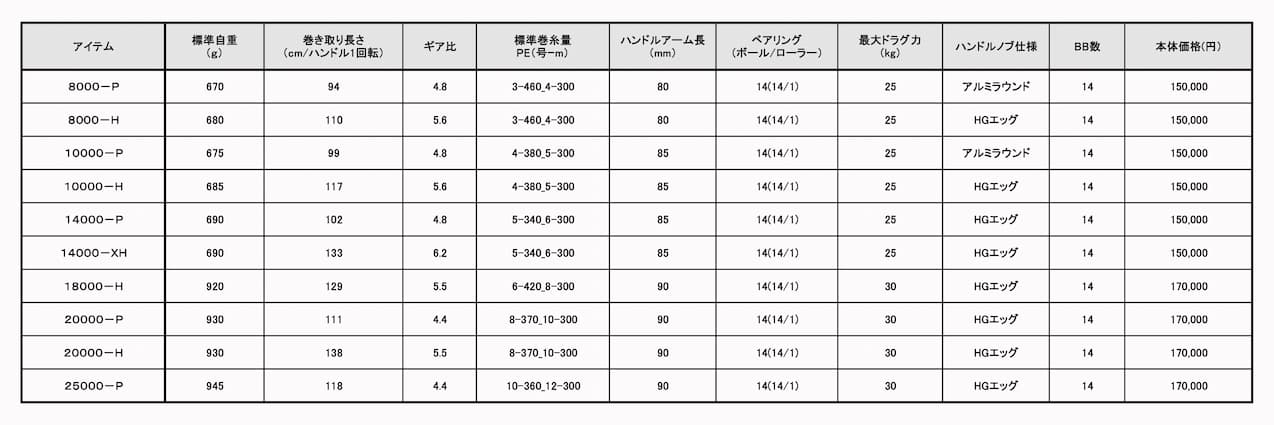

NEW SALTIGA Product Information

https://www.daiwa.com/jp/product/i25pggl

NEW SALTIGA special site

https://www.daiwa.com/jp/special/products/25saltiga