Reducing Heat-Induced Strength Loss While Applying Line Tension

Reeling in fishing line without damaging it Uoya x Studio Ocean Mark “Thread Winding Factory・ITOMAKI KOUJYOU” NEW Model for 2023

Winding line onto a reel is a necessary task for anglers. However, if this winding process is not done properly, it can lead to trouble, and the angler may miss the fish he or she has finally caught. This is why the UOYA line winding factory and the IK500 run tensioner were created, and in 2023, these line tensioners will be further evolved with additional items. If you are looking to catch your dream size fish, this is the item for you. We spoke with the staff of Studio Ocean Mark, the company that manufactures the new product, to find out more about it.

INDEX

When winding the line on the spool, it is important to wind the line without losing line strength!

When winding or rewinding line on a reel, tension must be applied firmly. If the line is wound too fluffy, the line will bite when a large fish hits, and likewise when a heavier jig is used, the weight of the jig will cause the line to bite. This also leads to line trouble when casting in casting games.

When lure fishing in saltwater, the main line used is PE line, which has tensile strength and is thin enough not to be affected by the tide. Therefore, if the line bites into the line wound on the spool, the frictional heat reduces its strength, and further biting can lead to line breakage. Other line problems are also likely to occur. Furthermore, if the line is not wound with a firm tension, it may not be possible to keep the line within the run capacity set for each reel. So you have to wind the line onto the spool while maintaining the proper tension, but this is not easy. In 2013, at the request of Uoya, Studio Ocean Mark produced and released the IK500.

Until the introduction of the IK500, when reeling in line, anglers were required to hold the plastic spool on which the line was wound from both sides of the spool using a cloth, or to use a device to apply tension from both sides of the plastic spool when reeling in the line by themselves, or to hold the line in front of the reel using a cloth or their fingers. When winding the line by oneself, it is common to use a device that can apply tension from both sides of the plastic spool, or to hold the line itself with a cloth or your fingers in front of the reel. However, it is difficult to maintain a constant tension in this way, and if the line is held down, heat is generated, which reduces the strength of the new line. The question was, “Is there any way to wind the line while maintaining a constant tension without causing heat or reducing the strength of the line?” (The product was developed in response to such a request from anglers. The IK500 was released in response to such requests from anglers.

Before the launch of the IK500, a full package model, the IK1000, which included a tensioner, bobbin stand, and reel mounting base, was introduced under the name “ITOMAKI KOUJYOU,” but at the time it was considered an expensive product and was used by pro stores for professional use. However, some anglers wanted to use it at home because of its quality, so the IK500, a tensioner that can be set on a table or work surface at home to enable firm line winding, was subsequently released. The IK700, which is a line holder and pedestal only, was followed by the improved IK750 ver. 2, and many professional anglers and stores have been using the “ITOMAKI KOUJYOU,” which includes a tensioner, bobbin stand, and pedestal.

Professional anglers, especially those who are fishing for big fish, are very careful in winding the line onto the spool. And when fishing for big fish, they wind a new line onto several spools. This is because the large fish that is hooked may be of a size that is hard to see, and anglers do not want to make a mistake due to a line break. This is where the line winding factory comes in. The line is wound on the spool with 100% line strength while being tensioned. In 2023, the ITOMAKI KOUJYOU has further evolved and released the IK500 ver. 2 line tensioner, the IK700BASE bobbin stand and pedestal, and the new, smaller IK300COMBO as models that can further reduce line damage during thread wrapping.

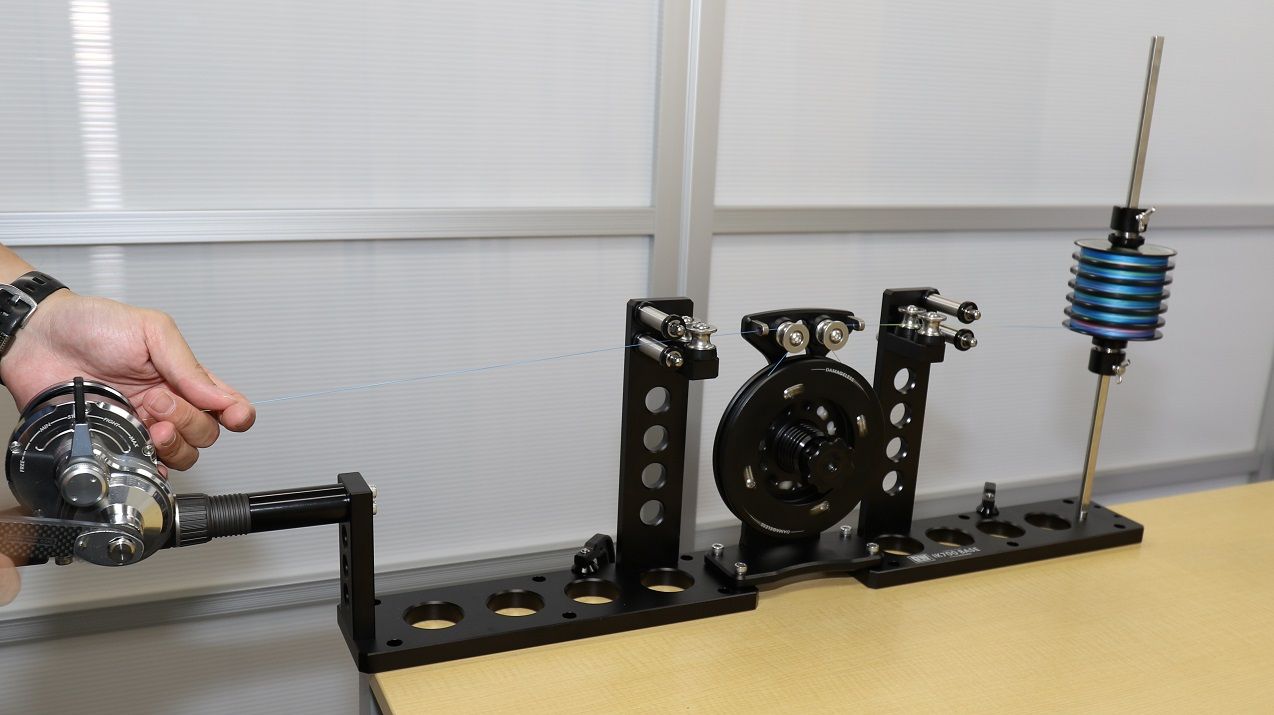

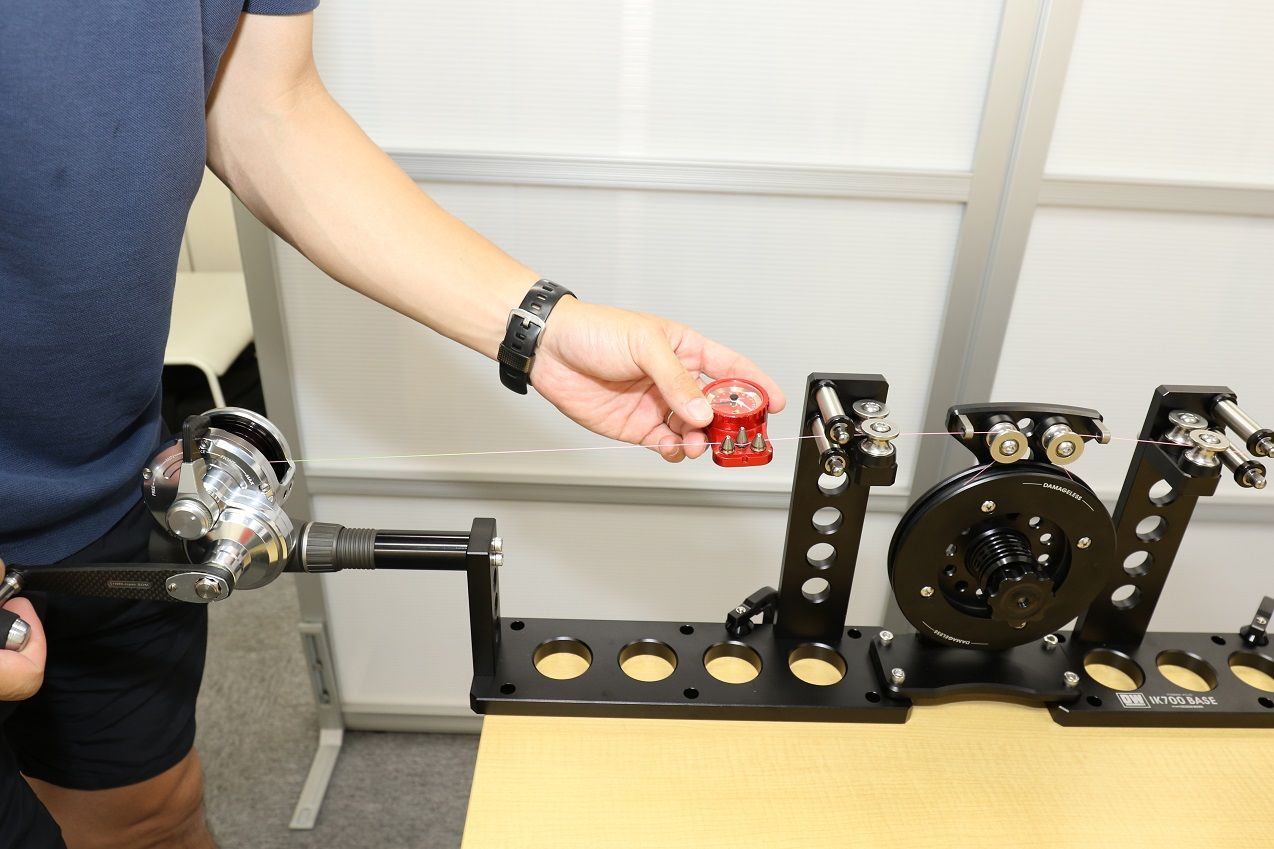

Evolution of the ITOMAKI KOUJYOU. the IK700BASE with the IK500ver2 in place during thread winding. the IK700BASE and IK500ver2 are gentle to the line and have evolved to allow fine tuning.

Here, the line is being wound using the IK300COMBO, which is easy to carry. You can see at a glance how compact it is.

Line tensioner “IK500 ver.2” that generates less heat

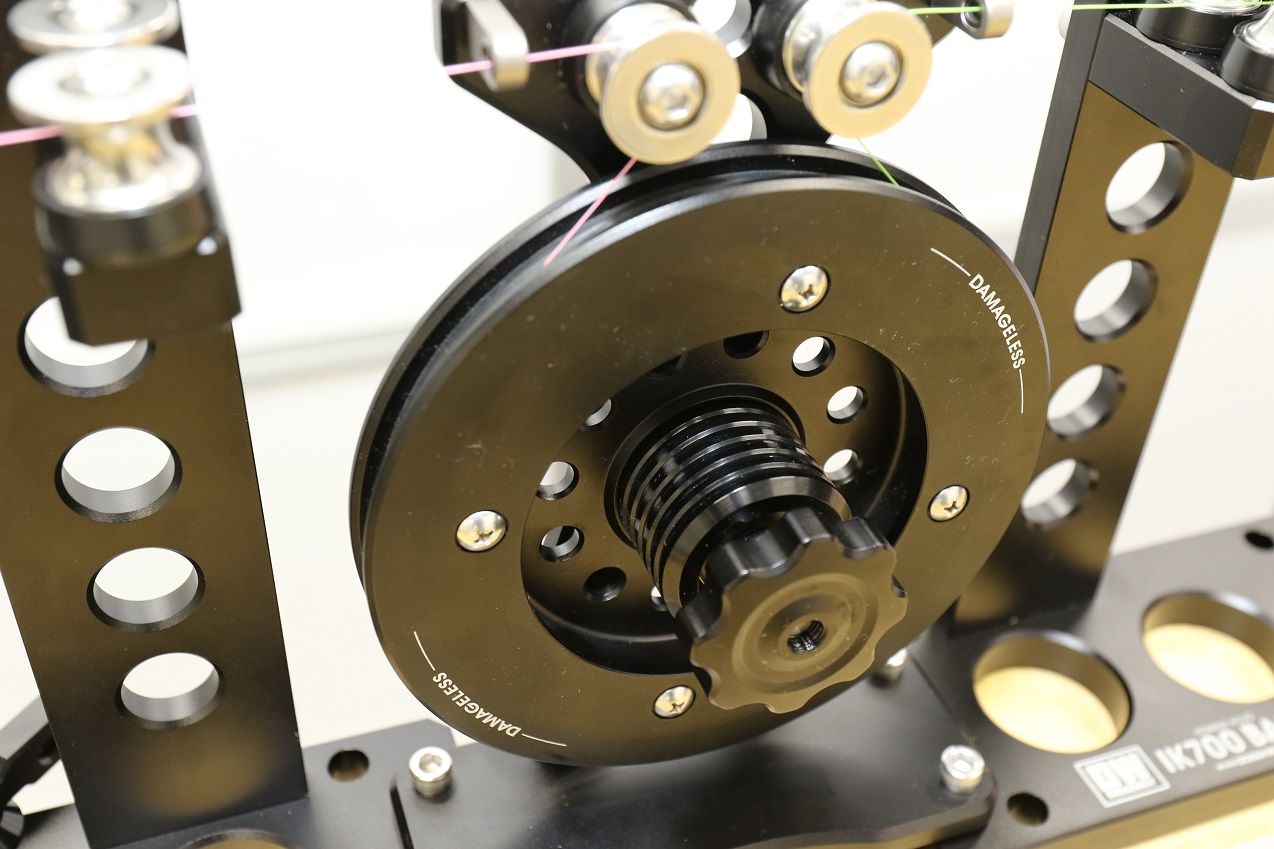

So what is the evolution of the IK500 ver.2 and IK700BASE? First of all, the line tensioner IK500 ver.2 has been evolved to cause less damage to the line. The IK500 line tensioner uses a large-diameter drum to first keep the line away from the rotating shaft, which is prone to heat generation, and then has rubber in between to block the heat from the rotating shaft. Furthermore, the drum section has a structure similar to that of a spinning reel’s drag, which allows the line tension to be adjusted. Of course, once that value is set, it can be wound all the way to the end without changing. It is difficult to keep applying the same amount of force using the simple method of holding down the line with a finger or cloth. Inevitably, there will be strong and weak areas. If the same tension is applied, it is possible to interrupt the reeling process to take a rest or do something while the line is being reeled in.

So what has changed in the new model? First of all, the spring in the knob has been redesigned to allow for more fine-tuning. The bobbin stand is mounted on the right side of the tensioner and the reel stand on the left side, but the part that stabilizes the line as it enters and exits the tensioner was coiled in the previous IK500, but in the IK500er2, this part is now a ceramic ring like a rod guide. The IK500er2 has a ceramic ring specification. This reduces damage to the line when the line is angled, and the ceramic specification eliminates problems caused by deterioration of the ring.

The dial in the center of the tensioner is turned to adjust how the line comes out. It is produced by applying the manufacturing know-how of Studio Ocean Mark’s spinning reel spools.

The IK500 ver2 is shown above and the previous model IK500 below. The IK500ver2 has evolved from the coiled line catcher of the previous model to a shape with a ceramic ring, making it more line-friendly.

IK700BASE” supplies line more smoothly to the tensioner.

Next, set up the bobbin stand and reel.

Next is the IK700BASE, which serves as a bobbin stand and a base for setting reels, which has also evolved to be more line-friendly and easier to use. First of all, this model is an evolution of the IK700, but it has undergone changes to the extent that it can be called a full model change. The main visual difference is that the bobbin stand side and the side for setting the reel are now separate. It is also lighter in weight. This makes it compact when stored, and the light weight makes it easy to insert and remove.

The IK700BASE has a separate structure that separates the left and right sides. The IK500Ver2 is set between them with screws.

This is the old model IK500 installed. The old IK500 can be attached by using a joint adapter (sold separately).

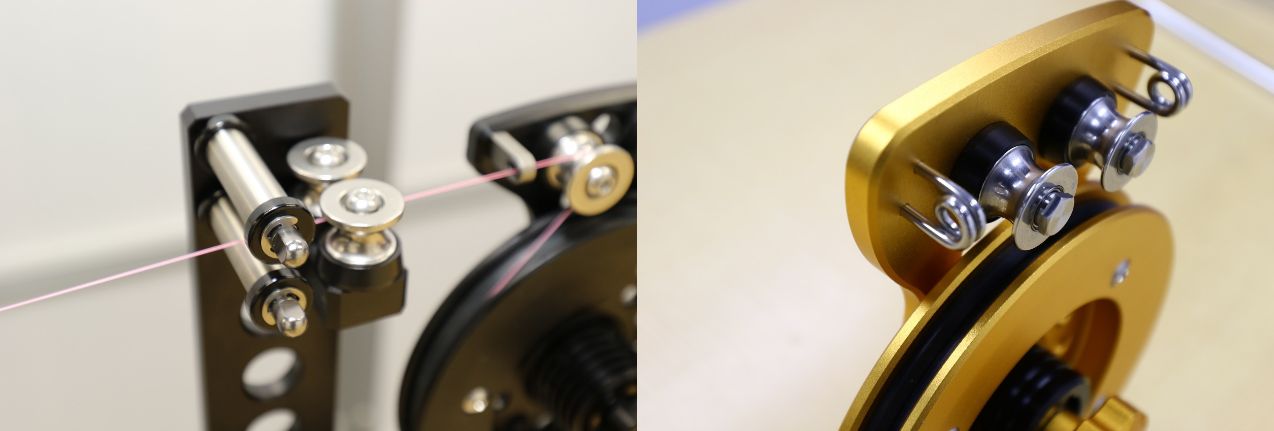

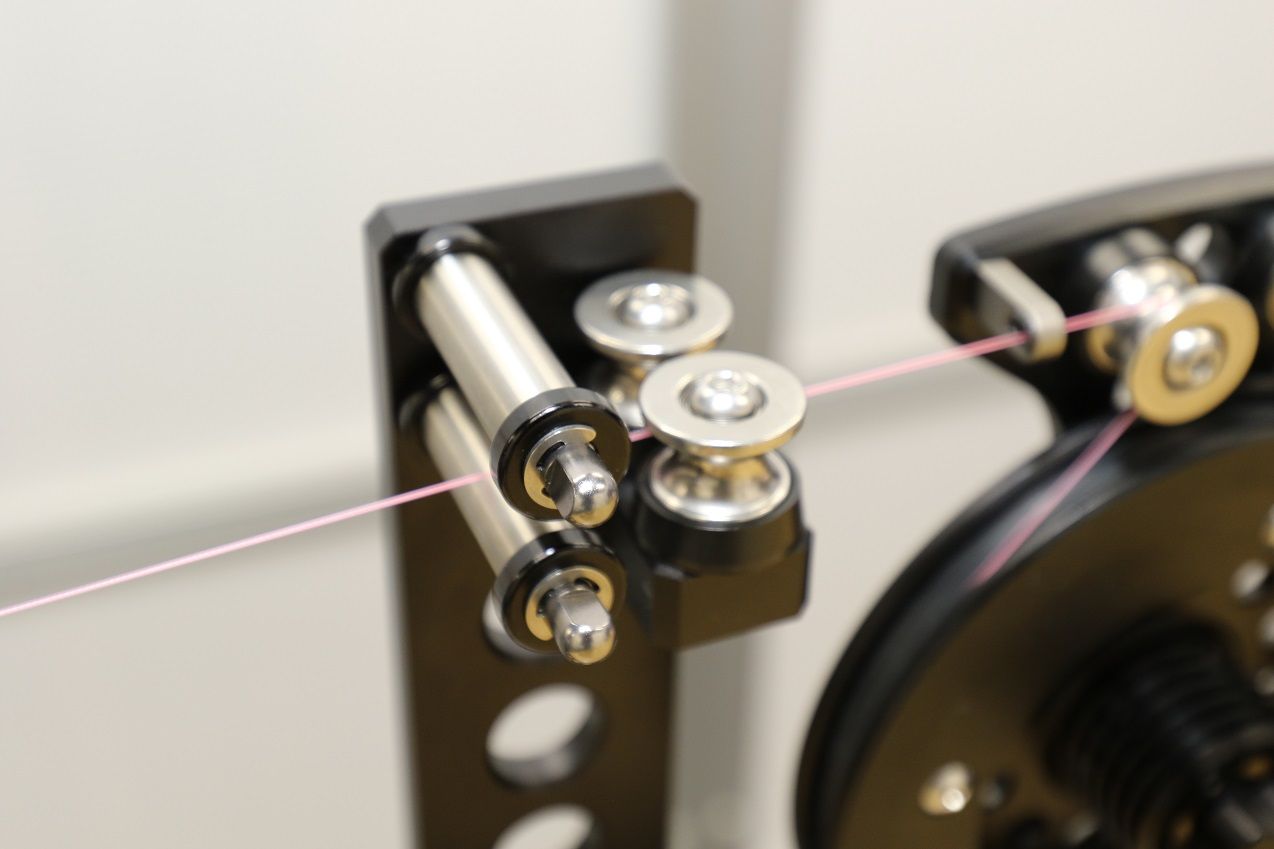

A further functional change is the roller part where the line passes through and where line shake is controlled. The roller section consists of vertical and horizontal rollers, which are placed on both sides of the tensioner when it is installed. This firmly controls the line coming from the line holder side and from the tensioner to the reel spool. With spinning reels, the larger the reel, the more the line shakes up and down, left and right. Also, with the line on the connecting spool, the line is swept diagonally in the direction of the tensioner. These are controlled in this section.

The line extending from the tensioner IK500ver2 to the reel spool and from the line holder to the tensioner is controlled by a combination of vertical and horizontal rollers.

In addition, the IK700BASE this time is also processed with angled edges where the line might touch, as shown in the photo above. This is to prevent scratches in case the line comes into contact with it. The IK700BASE can also be used with the conventional IK500, as shown in the photo above. In this case, screws (sold separately) are required. If you already have only the IK500, you may choose to purchase only the IK700BASE.

Incidentally, the IK500er2 and IK700BASE set supports lines from PE No. 2 to No. 15. This model is suitable for everything from targeting bluefish to dreaming of oversized targets.

A coupling compatible shaft is also included. The position can be adjusted with the upper and lower thumbscrews, so the line can be fed out without angling with the rollers.

A drag washer is inserted into the bobbin stand. While firmly holding the plastic spool, the washer prevents heat from being generated.

The “IK300COMBO” works well on expeditions.

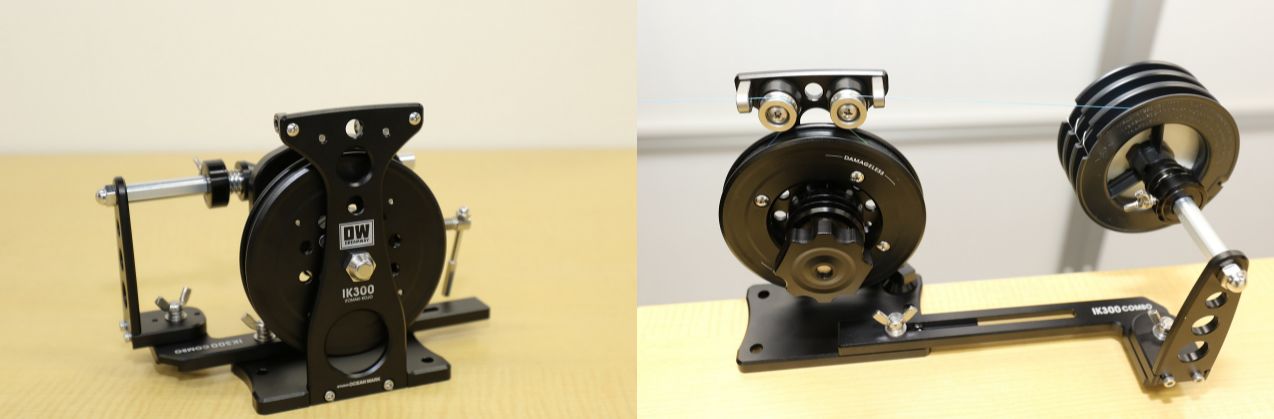

In 2023, the IK300COMBO was released as a new product. This model is considerably more compact than previous models, as can be seen from its appearance. When using it, the set of machined clamps can be removed, the variable part moved with a thumbscrew, and fixed to a desk or other surface with a clamp (vise), making it possible to take it on an expedition and use it. At home, it is compact and easy to store. Incidentally, this model is compatible with PE No. 0.8 to No. 6, making it the best match for light game enthusiasts, from casting games up to PE No. 6, jigging sunfish and yellowfin tuna, to mid- and deep-sea slow jigging and sea bass. The line holder pin is also available with an extension shaft (sold separately) for those who wind a large amount of line with a connecting bobbin.

Assembled and designed to be quite compact. Convenient for carrying around. With this model, it is possible to rewind line on an expedition.

Assembly

After removing the attached vise, the model can be assembled by loosening the thumbscrews and moving the vise.

The line holder part is designed with convex and concave parts so that it fits tightly and can be worked without shifting even after long hours of reeling in the line.

On the left is the standard shaft. Some people just wind the line on a connecting bobbin. For such people, an extension shaft is also available.

The included clamp (vise) is machine cut. It is possible to set the IK300COMBO firmly on a table or other surface.

Numbers for Winding Line on a Spool

So far, we have written that when winding line on a reel, while applying tension, thermal measures are necessary to prevent damage to the line. If too much load is applied to the line to be used, damage will be caused when the line is wound. There is a suitable load depending on the strength of the line. Studio Ocean Mark recommends that the number of line size x 0.7 = the number of kg to be set. For example, a No. 4 PE line would be 4 x 0.7 = 2.8 kg. This value is said to be appropriate without causing any trouble and without reducing line strength.

Incidentally, when winding line onto the reel spool, the line is first set in the line winding factory, at which point the line release value is measured with a scale (drag checker is recommended) and set. After that, the line is reeled in.

While adjusting the tension with the dial on the tensioner IK500ver2 or IK500, measure that value in front of the reel. When the correct value is reached, start winding the line.

By the way, all of the items introduced here cost a fair amount of money. However, they can be used for many years, and they wind the line more firmly and evenly, reduce line trouble, and most importantly, when a big fish hits, you will be able to fight it without any worries. And if you are able to catch that memorable big fish, the fish of your dreams, it is well worth considering the purchase. The fact that professional anglers who have achieved results are using this lure proves its value. If you can’t find it at your favorite store, check to see if they have a deal with Uoya, and if they do, you can order it from them.

Selling price

IK500ver.2 49,500 yen

IK700BASE 70,000 yen

IK300COMBO 49,000 yen

*Sold by: Uoya Co.

ITOMAKI KOUJYOU, explanatory video